Asp5010 Series Chemical Centrifugal Pump

Basic Info

Model No.: ASP5010

Product Description

Model NO.: ASP5010 Working Pressure: Low Pressure Pump Position of Pump Shaft: Horizontal Pump Mounting Height: Since Irrigation Centrifugal Pumps Usage: Pumps Capacity: 1500m3/H Trademark: Sanlian/Kubota Origin: Anhui, China Impeller Number: Single-Stage Pump Influent Type of Impeller: Single Suction Pump Pump Casing Combined: Horizontal Split Pumps Impeller: Closed Color: According to Customers′ Choices Head: 125m Specification: CE HS Code: 8413709990 Performance Range Outlet diameter: 25-200mm Capacity: Up to 1500m3/h Head: Up to 125m Working pressure: The highest 2.5MPa Temperature: The highest 160ºC

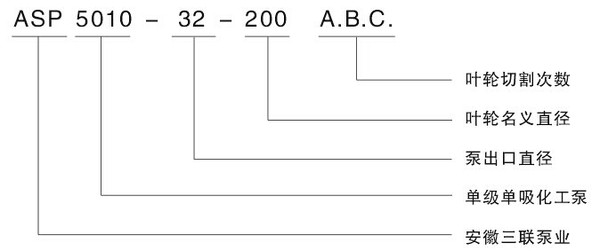

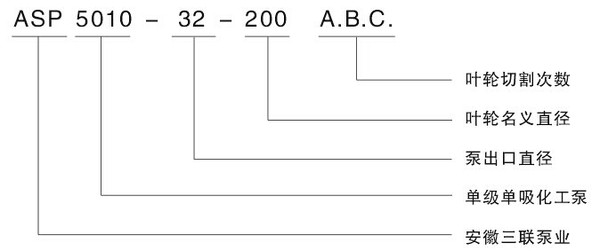

Description ASP5010 series Chemical Pump is Single Stage single suction cantilever Centrifugal Pump,which is designed by national standard ISO2858/ISO5199 with design theory that is scientific and reasonable,standardized and modularized to make sure the product operates steadily,economically and high efficiently and energy saving. Pump standard fits ISO,API,GB,ASTM,JIS,and the material of wet parts can be chosen according to different transmitted medium. Power supply that is 50Hz and 60Hz can be applied to ASP5010 series chemical pump. Application Area Power plant,steel and metal manufacturing,chemical plant,refinery,food industry,automobile industry,waste incineration plant,seawater desalting plant etc. Code Identification

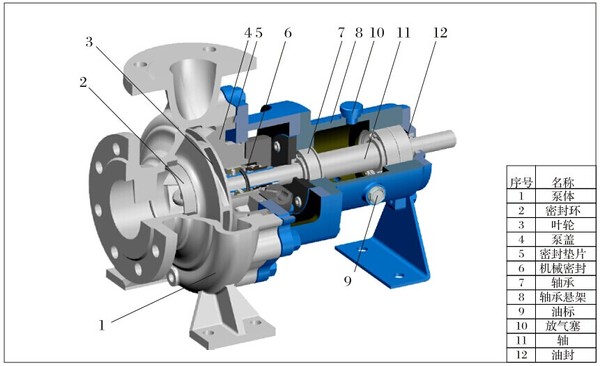

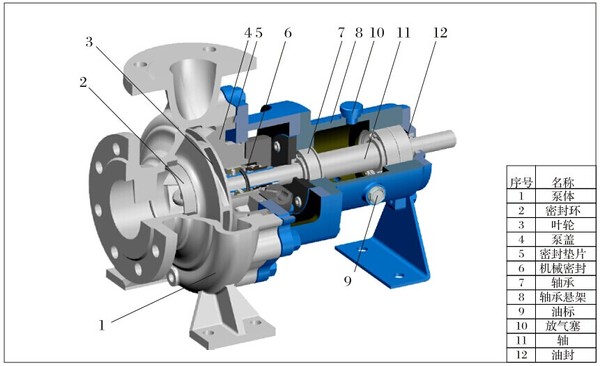

Structural Characteristics 1,Pump is designed by horizontal installation single stage cantilever. 2,Two angular contact bearings and one cylindrical roller bearing are applied on the bearing box,which can bear the radial force and axial force of pump efficiently. 3,Pulling part of bearing box is whole-back-pulling type.So there is no need to dismantle the outlet and inlet pipeline of pump at site,which shall be convenient for the maintenance of pump at site. 4,There is empty chamber in the pump cover to keep warm and to cool,which is suitable for the medium that needs to be kept warm or cooled. 5,Type of impeller includes closed impeller and open impeller.Closed impeller is used to transmit common medium,and open impeller is used to transmit corrosive liquid and liquid that can be easily crystallized or liquid that contains gas. 6,GB9115.2-2000 is applied on flange standard,dimension standard of outlet flange and inlet flange,which is equal to HG20592-97. 7,Wire thread is applied on the impeller nut to prevent it from loosening due to the vibration during pump operation or reverse. 8,Pump rotates clockwise,from the direction of driver end. 9,Shaft seal Seal chamber is designed according to API682 standard.And balancing-type single mechanical seal is taken as standard.Double mechanical seal or tandem type mechanical seal can be applied according to the requirements of user. Cartridge seal is wholly installed in the seal chamber,which makes the maintenance of sealing parts quick and convenient without being dismantled.Shaft seal can also be made into packing seal as the requirements of clients. Sectional Drawing

Contact us if you need more details on Oil Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Centrifugal Pump、Chemical Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Description ASP5010 series Chemical Pump is Single Stage single suction cantilever Centrifugal Pump,which is designed by national standard ISO2858/ISO5199 with design theory that is scientific and reasonable,standardized and modularized to make sure the product operates steadily,economically and high efficiently and energy saving. Pump standard fits ISO,API,GB,ASTM,JIS,and the material of wet parts can be chosen according to different transmitted medium. Power supply that is 50Hz and 60Hz can be applied to ASP5010 series chemical pump. Application Area Power plant,steel and metal manufacturing,chemical plant,refinery,food industry,automobile industry,waste incineration plant,seawater desalting plant etc. Code Identification

Structural Characteristics 1,Pump is designed by horizontal installation single stage cantilever. 2,Two angular contact bearings and one cylindrical roller bearing are applied on the bearing box,which can bear the radial force and axial force of pump efficiently. 3,Pulling part of bearing box is whole-back-pulling type.So there is no need to dismantle the outlet and inlet pipeline of pump at site,which shall be convenient for the maintenance of pump at site. 4,There is empty chamber in the pump cover to keep warm and to cool,which is suitable for the medium that needs to be kept warm or cooled. 5,Type of impeller includes closed impeller and open impeller.Closed impeller is used to transmit common medium,and open impeller is used to transmit corrosive liquid and liquid that can be easily crystallized or liquid that contains gas. 6,GB9115.2-2000 is applied on flange standard,dimension standard of outlet flange and inlet flange,which is equal to HG20592-97. 7,Wire thread is applied on the impeller nut to prevent it from loosening due to the vibration during pump operation or reverse. 8,Pump rotates clockwise,from the direction of driver end. 9,Shaft seal Seal chamber is designed according to API682 standard.And balancing-type single mechanical seal is taken as standard.Double mechanical seal or tandem type mechanical seal can be applied according to the requirements of user. Cartridge seal is wholly installed in the seal chamber,which makes the maintenance of sealing parts quick and convenient without being dismantled.Shaft seal can also be made into packing seal as the requirements of clients. Sectional Drawing

Contact us if you need more details on Oil Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Centrifugal Pump、Chemical Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Single Suction Centrifugal Pump

Premium Related Products

Other Products

Hot Products

Best Quality with Low Price Centrifugal Oil PumpAutomatic Hydraulic Control ValveLec Series Pump Electric Control PanelSJB Diesel Driver Deep Well PumpZs Type High Quality Heavy Duty Minerals Processing Slurry PumpUL List Centrifugal Fire Fighting Water PumpVertical Axial Flow Pump (900HLB16)Emergency Movable Water Pumps with Trolley or TrailerZWL Micro-Computerized Non-Suction Pressure Constant-Flow Water Supply EquipmentMulti-Stage Sectional Type Centrifugal Water PumpMulti-Stage Fire Fighting Pump with Chinese First UL List PumpSLW Series Horizontal Centrifugal PumpHigh Quality Wq Submersible Sewage PumpsSlow Split Casing Centrifugal Pump (SLOW800-980)Double Suction Split Casing Pumps (SLOW)China First Fire-Fighting Centrifugal Pumps with UL Certificate